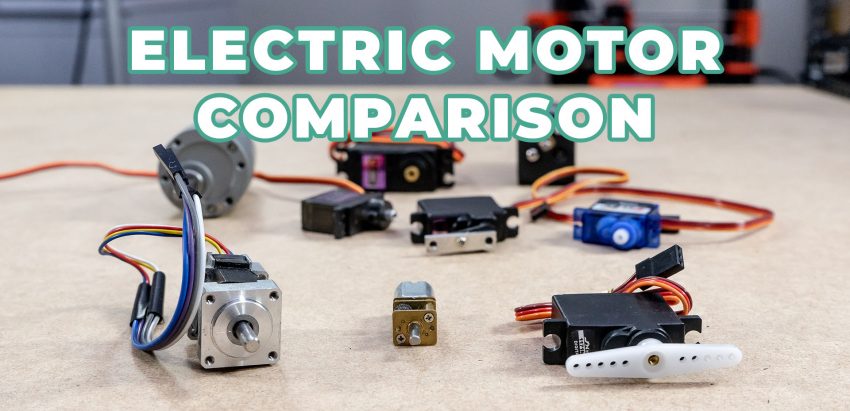

Need a motor for your project, but not sure which type to get? We offer a few different varieties of motor controlling function boards. So we hope, that this rundown on the difference between DC, Servo and Stepper Motors will help you decide what motor is best for you to use!

DC Motors

DC (Direct Current) motors are two wire (power and ground), continuous rotation motors. When these wires are connected to power supplies, a DC motor starts to spin until that power is removed. Most DC motors run at a high RPM (revolutions per minute). DC motors could be used for computer cooling fans, radio controlled cars or other automotive applications.

Mostly speed of DC motors is controlled using pulse width modulation (PWM). Using this technique we are rapidly pulsing the power on and off. The percentage of time spent cycling the on/off ratio determines the speed of the motor. For example, if the power is cycled at 50% (half on and half off), then the motor will spin at half the speed of your maximum speed (fully on). Each pulse is so rapid that the motor appears to be continuously spinning with no stuttering.

Servo Motors

We can talk about servo motors as an assembly of four things: a DC motor, a gearing set, a control circuit and a position-sensor (usually a potentiometer).

In industry servo motors are known as motors that can be controlled most precisely. Comparing servo with standard DC motors, servos usually have three wires (power, ground and control). Power to servo motors is constantly applied. Servo controller regulates the current draw to drive the motor. These motors are designed for more specific tasks where position needs to be defined. Moreover servo motors are used for accurate tasks, for example, to move robotic arm or robot leg within a certain range, move camera to certain object and etc.

Although, we must mention that servo motors do not rotate freely like a standard DC motor unless it’s modified for continuous rotation. These type of motors do not have a limit on its range of motion and instead of having the input signal determine which position the servo should rotate to, the continuous rotation servo relates the input to the speed of the output and direction. However, for most of the servo motors the angle of rotation is limited to 180 degrees back and forth. Servo motor receives a control signal that represents an output position and applies power to the DC motor until the shaft turns to exact position, determined by the position sensor.

Unlike DC motors, to control servo motor PWM signal is used. The duration of the positive pulse that determines the position, rather than speed, of the servo shaft. A neutral pulse value dependent on the servo (usually around 1.5ms) keeps the servo shaft in the centre position. Increasing that pulse value will make the servo turn clockwise, and a shorter pulse will turn the shaft anticlockwise. Servo control pulse is usually repeated every 20 milliseconds (depends from servo motor). We always must tell the servo where to go, even if that means remaining in the same position.

When a servo receives command to move, it will move to the position and will try to keep that position, even if external force pushes against it.

Stepper Motors

A stepper motor is essentially a servo motor that uses a different method of control. Stepper motors utilize multiple toothed electromagnets arranged around a central gear to define position.

To control stepper motor, we need an external control circuit or micro controller (e.g. a Raspberry Pi or Arduino) to individually energize each electromagnet and make the motor shaft turn. When first “A” and second “B” electromagnets are powered, motor shaft aligns between them. When “A” is switched off, and “B” switched on, the gear rotates to align with magnet “B”. With each electromagnet around the gear we turn them ON and OFF in turn to create rotation. Each rotation from one electromagnet to the next is called a “step”, and thus the motor can be turned by precise predefined step angles through a full 360 Degree rotation.

The design of the stepper motor provides a constant holding torque without the need for the motor to be powered ON.

g

Summary

This is a short overview of pros and cons of DC vs Stepper vs Servo motors. Hopefully it should help you make a more informed choice with your needs for you project.

DC Motors:

Fast, continuous rotation. Finally they are used for anything that needs to spin at a high RPM e.g. car wheels, fans, drills etc.

Servo Motors:

May be very fast, high torque, very accurate rotation within a limited angle. Generally a high performance alternative to stepper motors, but more complicated setup with PWM tuning. Suited for robotic arms/legs etc. Servos require a feedback mechanism and support circuitry to drive positioning.

Stepper Motors:

Quite slow, precise rotation, easy set up and control. Advantage over servo motors in positional control where turn angle is not limiter. Stepper motors are suited for 3D printers and similar devices where position is fundamental.

Stepper vs Servo: The Verdict

Servo control systems best suit to high speed, high torque applications that involve dynamic load changes. Stepper control systems are less expensive and are optimal for applications that require low-to-medium acceleration, high holding torque, and the flexibility of open or closed loop operation.