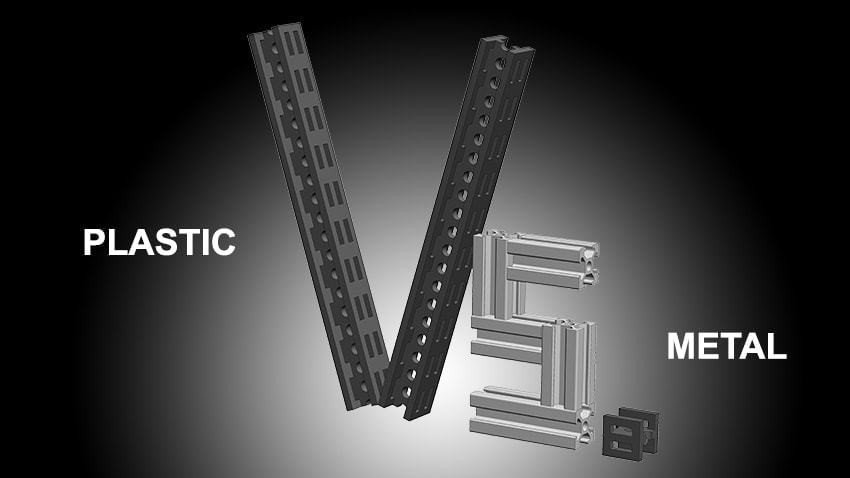

Some makers are not sure if they need plastic or metal structure for their project. In this post we are explaining, why Totem strongly supports plastic parts. Spoiler: it’s all about the custom design.

Makers have all kinds of motors, PCB’s, batteries, half made projects, lying around. It is frustrating, because mounting holes of components almost never match. Plastic parts are much more suitable to overcome this issue, because they are easier to modify and adjust.

Tailor Beams and Boards to your project

We made Totem structural parts to be customized. The Beam is 40 cm length and the builder can cut to shorter parts at every 1 cm. Made a mistake? No worries, just cut another one! Totem Board is 10 cm x 10 cm and it can be cut at every 5 mm (even at 45 degrees). We designed specialized tools for beam and board cutting. Fast and easy cut! More about Totem tools here.

Other cutting tools are handy as well. Drill a hole for larger diameter bolts, shaft or an axle. Use cutting pliers if there is a corner sticking out. Combine this with Totem adjustable brackets and you get lots of mounting options.

Check out here the ways you can mount electronic boards.

Light weight

Having light weigh parts can be a direct indicator of how well the model will work. Let’s say one is building robotic arm. The lighter the construction, the less stress for the motors, the heavier object it will be able to lift. Same thing for walking robots, or drones!

More freedom to design

Most hobby construction systems have a grid. As long as one needs 90 degree connection, they all work. But what happens when the model needs 45 degrees angle or 60? It is very likely, parts will no longer match.

Totem beams and boards give the ability for mounting holes to be shifted. Most of the times, there is only 1-2 mm miss-match. That is a lot for metal, but plastic parts can be bent or twisted. Take a look at the picture below. The drawing shows assuming parts are totally straight. It is very clear, the bottom connection is off the grid. The picture on the right, shows real assembly of Totem parts. All connections look perfect. If parts could not be deformed, the design would be very limited due to grid restrictions.

Model vs. real assembly

Press fit connections

Next big advantage of Totem plastic beam is the ability to have a press fit connection for nuts and brackets. When they enter the slots, beam walls hold inserted parts. Combine this feature with the Totem magnetic screwdriver and forget about the hassle of constant dropping parts on the floor.

Press fit Nuts and Brackets

Aesthetics

Scratched anodized aluminium

When we present our models at exhibitions, most of the people can not tell what kind of materials we use. They are light weight, but strong and feel solid.

Do not wait any longer, start making with plastic too!